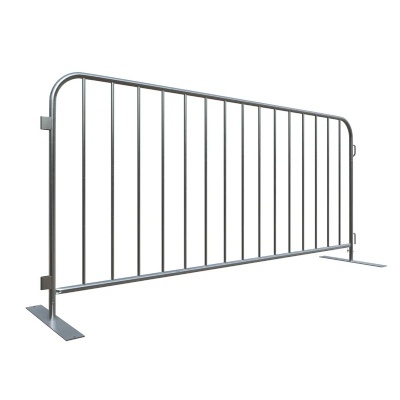

Metal Barrier Factory OEM and ODM service-Glory Fence

Glory Fence is a metal barrier factory that specializes in producing metal barriers. Metal barrier is a popular tool for crowd control, event management. We are committed to maintaining the highest standards of quality, ensuring that each barrier meets rigorous safety and durability tests before reaching the customer.

The production process of metal barrier

The process involves several detailed steps to ensure the final product meets the highest standards of quality and durability. Here’s a step-by-step breakdown:

1.Raw Materials:

The process starts with the purchase of high-quality raw materials. The factory notifies clients when this phase begins, ensuring the materials meet the required specifications for strength and durability.

2.Cutting:

The selected raw materials are then precisely cut into the required shapes and sizes.

3.Punching &Tube Bending

After cutting, the materials undergo punching to create holes needed for assembly. This step is crucial for the alignment of different barrier parts.

The workers bend the tube into the desired shapes according to the design specifications. This process is crucial for forming the main frame of the barriers.

4.Swaging (Tube Reducing):

This involves reducing the diameter of the tubes at one end to allow them to fit into each other or additional components.

5.Welding of metal barrier

We will weld all the parts are welded together to form the complete barrier structure. At the same time, do not forget the check quality the welding point to make sure it's stable enough.

6.Zinc Powder Spray or Hot Dip Galvanizing

After welding, the workers will spray the welding points with zinc powder to prevent rust and increase longevity. This stage is crucial for ensuring the barriers can withstand various weather conditions.

Hot-dipped galvanizing is for low-carbon steel tubes. The barriers are submerged in molten zinc, providing a thick, durable coating. The thickness of zinc must be more than 42 millimeters.

7.Quality Inspection of metal barrier

Each barrier undergoes a thorough quality inspection to ensure it meets all safety and durability standards. Clients are involved in this phase to confirm that the product specifications are met.

8.Packaging and Shipping

Once approved, we will pack the barriers and prepare for shipping. We will notify the clients about the dispatch details, ensuring a smooth delivery process to the desired location.

Throughout these stages, communication with clients is necessary to ensure transparency, satisfaction, and adherence to specifications.

We offer comprehensive OEM and ODM services to meet the needs of all kinds of clients. Whether you are a wholesaler or a retailer, we can provide customized solutions tailored to your requirements. Our services include product design, manufacturing, and quality control to ensure that you receive high-quality products that meet your specifications. We have been working closely with our clients to ensure the success of each project. Choose us for a smoother and worry-free business experience.

Metal Fence Manufacturer & Supplier

Metal Fence Manufacturer & Supplier